Revolutionizing cookware for half a century

When the first fully bonded pan rolled off our Pennsylvania assembly line 50 years ago,

it forever changed how cookware was crafted.

OUR HISTORY

Changing the world of cookware since 1971

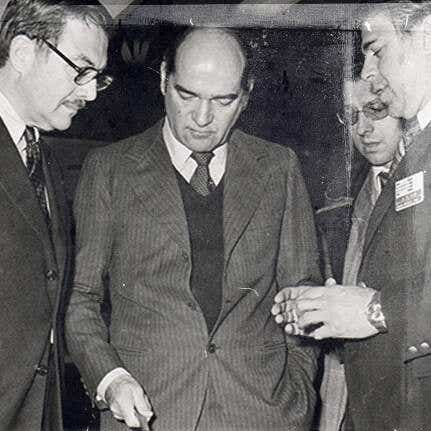

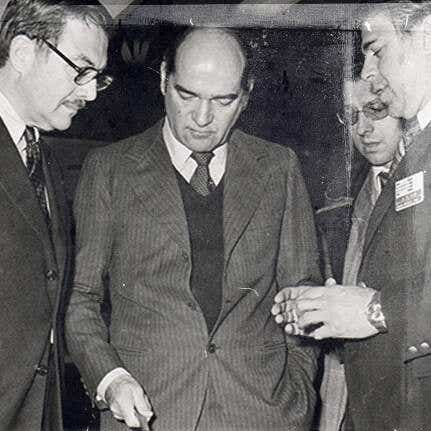

The man of metal

Our founder, John Ulam wasn’t a professional chef or a product engineer. He just happened to know metals better than anyone. A renowned metallurgist, John had more than 75 patents for metal crafting and his innovations transformed the metals used to manufacture car parts, build airplanes, and even mint coins.

Reinventing the pan

Being an avid home cook, John wondered what would happen if he applied his patented metal crafting methods to cookware. So in the spirit of invention, he took layers of stainless steel, bonded them with aluminum, and shaped them into pans.

All-Clad is born

This new bonded cookware cooked food more evenly, was easy to clean, didn’t alter flavors, and didn’t tarnish or warp. It was such a hit, John started our company, All-Clad Metalcrafters, in 1971. Shortly after, he opened a factory near his hometown in Western Pennsylvania.

“Don’t worry about bells and whistles,

worry about delivering maximum performance.”

- JOHN ULAM, ALL-CLAD FOUNDER

OUR MISSION

Crafted with passion to ignite yours

The same enthusiasm and creativity cooks put into every dish they make, we put into every piece of cookware we make. To us, cooking to perfection is more than just a saying, it’s our mission. And we challenge ourselves to help all cooks accomplish that goal every day.